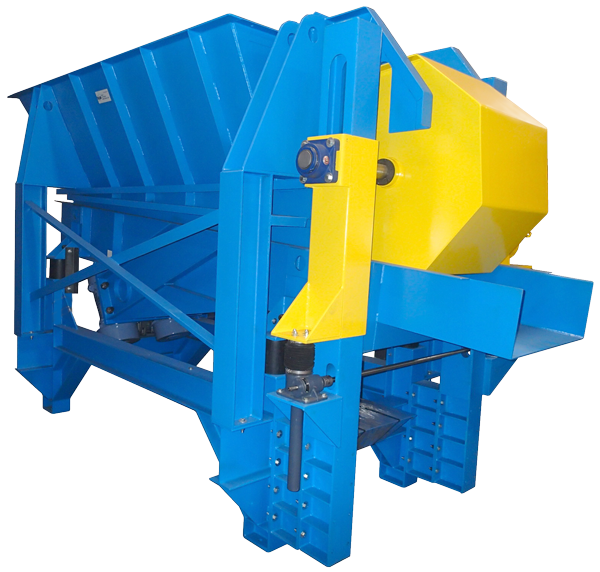

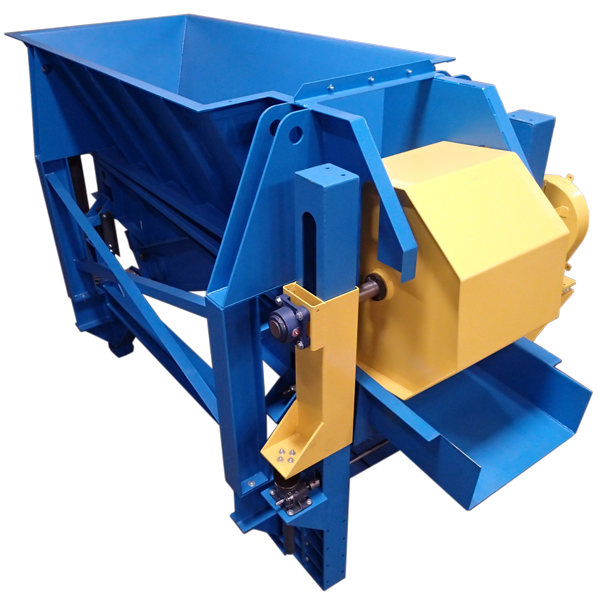

Metering Batch Feeders

Vibratory Metering Batch Feeders Model CFL-MF-48242-77-8-2

Material: ASR and Non-Ferrous Metals

Bulk Density: 19-38 Lbs./Ft.3

Rate: 45 TPH at 50 downslope

Metering Batch Feeders are ideal for any application where materials need to be conveyed with an even flow of distribution. Materials are placed in a feeder with 5-20 cubic yard capacity and are then evenly distributed on the conveyer. Variable speed control allows for the consistent flow of material to meet your bulk processing and conveying requirements.

- Loading Hopper:

- Approximately 16 cubic yard capacity

- Includes a 44.5″ hexagon rotating drum which for assisting in leveling, anti-bridging and metering of material in the feeder pan

- Automatic screw jack for adjusting metering height included

- Motor and gear-box provided

- Drum support frame is adjustable to position drum properly above the feeder

- Tray Size:

- 48” wide by 242” long

- Drive:

- Dual Model KEE-77-8 Rotary Electric Vibratory Motors

- TENV design with fully adjustable eccentric weights

- 900 RPM fixed, 6 HP each, 12 HP total.

- Power Requirements:

- 460 Volt, 3 Phase, 60 Hz

- Feeder Isolation:

- Marshmallow Mount isolation

- Support base provided by BPS

- Approximate discharge elevation: 57”

- System Controls

- Quoted as an option

- Materials of Construction:

- Mild steel

- Finish Paint:

- Blue enamel

Option I

System Controls

- A/C inverter drive for the Vibratory Feeder

- Motor starter for the Rotating Drum

- Drives to be mounted in a NEMA 12 Enclosure and located in the power distribution area

- Operator control station rated at NEMA 4 to be located outside near the machine

- All wiring will be completed to a terminal strip for easy field installation

- Electrical requirements: 460V, 3PH, 60Hz

Option II

Continuous Height Measurement with Limit Switch

- High/Low limit switch fro metering drum

- Encoder for continuous height measurement

- Prewired to local terminal junction box

- Wendt is responsible for all HMI/PLC programming