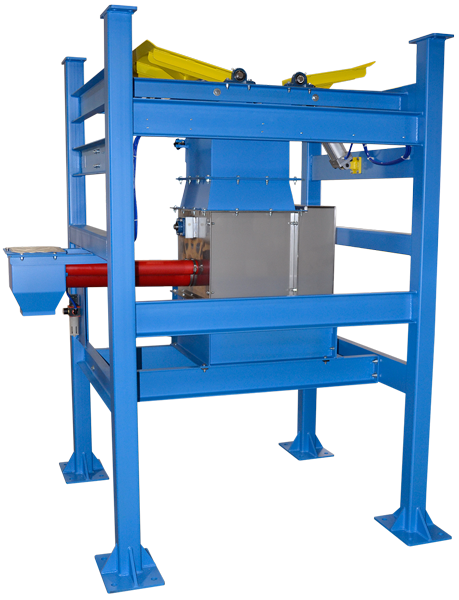

Twin Screw Feeder

The BPS Twin Screw Feeder is designed for precise batching and weighing applications. The feeder incorporates two Helixes into one hopper, creating a compact design for spaces that do not allow for multiple individual screw units. The feeder’s dual helix design combines fast, high volume filling with accurate dribble flow at the end of the cycle.

- Rated at 17 cu. Ft. per hour and 283 cu. Ft. per hour, at maximum RPM with 100% efficient conveyable product and no slippage

- Longer Helix extensions

- Integral supply hoppers

- Explosion-proof motors and controls

- Gravimetric designs with integral scales

- Portable bases on wheels with levelizing jacks

- Hopper with air pads to prevent product bridging, with on/off control

- SCR variable speed flow control

- Regreasable lubricated bearings

- Air purged shaft seal at rear to eliminate product leakage

- 2 helixes 1-1/2” and 4” diameter mounted on 18” x 22” hopper

- 304 Stainless product contact surfaces

- Large Helix is 4″ dia. for maximum flow

- Small Helix is 1-1/2″ dia. for dribble flow

- Two 1-HP DC motors with chain-type drives

- Helix standard extension is 16″ from face of hopper

- 18” x 22” inlet, only 30” overall

- Batching to weigh hoppers

- Low loss in weight scale monitored flow

- Low loss in weight batch applications with scales

- Drum and Pail packout lines

- Multiple units employed for recipe-type batching, typically computer-controlled

Our Twin Screw Feeders are an ideal solution for multiple industries and materials. Contact us to learn more about how we can customize your unit to fit your facility’s needs.